- Home

- About

- Products

- Contact Temperature Sensors

- Cables & Wires

- Mineral Insulated Cables

- Nickel & Thermocouple Alloy

- Industrial Heaters

- Heating Cables and Mats

- Non Contact Temperature Sensors

- Industrial and R&D Furnaces

- Temperature Calibrators

-

Circulating Chiller

- Services

-

Special Products

- Thermal Profiling System

- Industries

- Resources

- Contact Us

- Shop

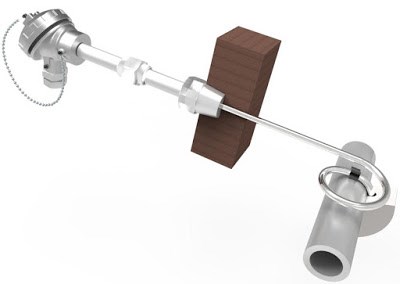

Skin Type Thermocouple

Skin Type Thermocouple are designed to measure the temperature of the body. It is bonded to the surface of the body to which temperature is to be measured through a insulating pad, so that it collects temperature. This model of thermocouple is typically used with in high temperature industry and/or corrosive environments where fast and accurate temperature measurement is critical.

How to select Skin Type Thermocouple?

The most important consideration for effective Skin Type Thermocouple is its design which can provide repeatability, durability and accuracy. To achieve these functions thermocouple must incorporate with its design which should provide excellent insulation properties , material compatibility and good physical contact with the tube and it should also have the ability to withstand high radiant temperatures and stresses and in some cases harsh combustion chemistry.

Installation of Skin Type Thermocouple

Mostly Skin Type thermocouple are directly welded to the surface to which we have to measure the temperature with thermally insulating pad so that only surface temperature is collected rather than surrounding air temperature. For a thermocouple to work at its optimum range, the thermocouple sheath must remain in close contact with the tube. The weld pad should be positioned at the critical point and the remaining cable should be routed away from the direct heat – along the coolest side of the vessel. This installation technique is important as it allows the thermocouple to utilize the process tube as a heat sink.

In addition to the weld pad, expansion loops design can be considered. A furnace can experience a movement of between 50 mm and 350 mm, from start up , to reach its process temperature. If such incremental expansions are not considered through the integration of expansion loops, the Skin Type Thermocouple will be subjected to strain and even breakage. Expansion loops are therefore recommended to ensure the optimum lifetime of the thermocouple helping to reduce commissioning and maintenance problems.

Types of Skin Type Thermocouple

Knife-Pad :

- Knife-Pad design includes a machined v-shaped block that is welded to the mineral insulated cable.

- Compaction of the mineral insulation inside of the Knife-pad protects the measuring junction from radiant temperature influences.

- Thermocouple junction welded into the base of the Knife-pad.

- Knife-pad block is designed to minimize the conducted heat influence from the mi-cable.

- Designed to limit the influence of high radiant temperature at the measuring point.

- Material compatibility for various service conditions.

- No special machining of the contact block is required to match the tube profile.

- The narrow v-shaped block allows a full penetration weld between the junction and tubesurface. This eliminates potential air gaps and substantial measurement inaccuracies.

- Fast temperature response behavior combined with reliability.

- Higher accuracy can be achieved with the addition of an optimized shield.

Bolt Sensor :

- The Bolt Sensor has a shield incorporated into its design.

- The Bolt sensor is filled with ceramic cement creating a large insulation factor .

- The Bolt sensor is contoured to match the tube geometry.

- The Bolt sensor is designed to minimize any air space between the ceramic surface of the Bolt and tube surface.

- Thermocouple junction has an interference fit with the tube surface when the Bolt is welded in place.

- Only single pass welding is required during installation.

- A clamp attachment is available when welding is not an option.The Bolt Sensor has a shield incorporated into its design.

Weld Pad:

- Weld Pad is an inexpensive design.

- Less accurate than the Bolt and Knife-Pad designs while maintaining similar repeatability.

- Designed for flat or curved surfaces.

- The pad is notched to match the mi-cable diameter. This allows the thermocouple junction to be in close proximity to the measuring surface.

- A shield option is available for greater accuracy.

- Compact design allows for ease of installation when there are space limitations.

- Pad can incorporate any mi-cable diameter.

- A continuous single-pass weld from the pad to the tube surface is sufficient for attachment.

- Weld pads can be mounted longitudinal or right angled to the pipe surface.

Washer Pad:

- Accuracy less than Knife-Pad,Bolt Sensor.

- Easy and hassle free installation.

- Replaceable.

Difference between Skin Type Thermocouple from other thermocouple

Skin Type thermocouple are never used as a shield they are directly connected to the surface of the body to which temperature is to be measured whereas other thermocouple cannot show this property.

Application

- Chemical and petrochemical industries.

- Energy and power plant technology.

- Furnaces, kilns, ovens and boilers.

- Oil and Gas industries.

- Power and utilities.

- Pulp and paper.